Hydraulic Crimping Machine

Company introduction

Besides hydraulic hose crimpling machine, our company also provides experienced professionals and highly skilled construction workers. You can customize hydraulic crimping machine according to your needs. Our products have been exported to Russia, Australia, Suriname, Vietnam, Malaysia, North Korea, Kazakhstan, Brazil, Africa, Nigeria, Oman, Macedonia, Uganda, Bolivia and other countries.Introduction of hydraulic crimping machine

Our hydraulic hose crimping machine is mainly used to process metal sheets into desirable shapes. During this process, the long strip of sheet metal is passed through sets of rolls mounted on consecutive stands. Our hydraulic crimping machine is an ideal choice for producing constant-profile parts with long lengths and in large quantities.Characters of hydraulic crimping machine

1. This hydraulic hose crimpling machine is highly efficient and fully automatic.2. It has complete range of dimensions. You can choose light duty or heavy duty.

3. Products of this hydraulic crimping machine is used for the surface of desks, stainless steel kitchen utensils, electric appliance box cabinet lighting products, metal furniture and other areas.

Features of architecture with arched roof made by simple curving machine

1. Light weight, high strength, good flexibility and superior shock resistance.2. Safe reservation, good wind resistant and seismic resistant ability.

3. It has precise and excellent connection spots because of the following characters, like variable design styles, strong adaptability, scientific design, and advanced construction way.

4. These constructions made by curving machine for roll forming have beautiful appearance, bright color and fluent lines.

5. You can also combine different shape constructions with straight slot board and traditional structure. You can increase space for your house by adding one layer on your roof or adding one arch between two structures.

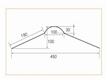

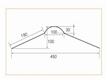

Main technology parameter of hydraulic crimping machine

| Main technology parameter |

|

| Appearance method | 1500×1300×1000 |

| Install method | Vertical |

| Angle range | 0~90 degree |

| Speed | 90degree / 4min |

| Shaft | 4 |

| Thickness | 0.3mm-0.5mm |

| Radius min | 450mm(semi-circle Radius550mm) |

| Power | 3KW |

| Model material | 40Cr,quenching and azotizing |

Related Products:

Hydraulic Crimping Machine

Hydraulic Crimping Machine

Glazed Tile Forming Machine

Glazed Tile Forming Machine

Spare parts

Spare parts

Ridge Cap Forming Machine

Ridge Cap Forming Machine

Roof Sheet Forming Machine

Roof Sheet Forming Machine

Deck Floor Roll Forming Machine

Deck Floor Roll Forming Machine

Punching machine

Punching machine

Leveling Machine

Leveling Machine

Glaze Tile Making Machine

Glaze Tile Making Machine

Double Deck Forming Machine

Double Deck Forming Machine

Container Board Forming Machine

Container Board Forming Machine

Light Keel Roll Forming Machine

Light Keel Roll Forming Machine

Glazed Tile Roof Machine

Glazed Tile Roof Machine

Roll Shutter Door Forming Machine

Roll Shutter Door Forming Machine

Corrugated Iron Machine

Corrugated Iron Machine

Slitting Machine

Slitting Machine

Color Stone Roof Forming Line

Color Stone Roof Forming Line

Auto Change Size C Purlin Machine

Auto Change Size C Purlin Machine

Ridge Cap Tile Forming Machine

Ridge Cap Tile Forming Machine

Corrugated Metal Roofing Machine

Corrugated Metal Roofing Machine

Glazed Sheet Making Machine

Glazed Sheet Making Machine

Corrugated Roll Forming Machine

Corrugated Roll Forming Machine

Metal stud and track roll forming machine

Metal stud and track roll forming machine

Glazed Tile Roll Forming Machine

Glazed Tile Roll Forming Machine

Glazed Roof Tile Forming Machine

Glazed Roof Tile Forming Machine

Keel Roll Forming Machine

Keel Roll Forming Machine

Light Steel Profile Machine

Light Steel Profile Machine

Corrugated Iron Sheet Roll Forming Machine

Corrugated Iron Sheet Roll Forming Machine

Metal Roof Making Machine

Metal Roof Making Machine

Hydraulic Curving Machine

Hydraulic Curving Machine

Double Roof Sheet Machine

Double Roof Sheet Machine

Glazed Aluminum Roofing Machine

Glazed Aluminum Roofing Machine

Pre-cutter

Pre-cutter

Decking Forming Machine

Decking Forming Machine

C Purlin Machine

C Purlin Machine

Simple Curving Machine

Simple Curving Machine

Corrugated Galvanized Sheet Machine

Corrugated Galvanized Sheet Machine

Film Coating Machine

Film Coating Machine

Metal Profile Sheet Making Machines

Metal Profile Sheet Making Machines

Car/Container Board Forming Machine

Car/Container Board Forming Machine

Light Steel Frame Roll Forming Machine

Light Steel Frame Roll Forming Machine

Automatic Decoiler

Automatic Decoiler

EPS Sandwich Panel Producing Line

EPS Sandwich Panel Producing Line

Deck Floor Forming Machine

Deck Floor Forming Machine

Double Layer Roof Sheet Forming Machine

Double Layer Roof Sheet Forming Machine

Corrugated Aluminum Sheets Machine

Corrugated Aluminum Sheets Machine

5 Ton Hydraulic Decoiler

5 Ton Hydraulic Decoiler

Hydraulic Bending Machine

Hydraulic Bending Machine

Metal Panel Forming Machine

Metal Panel Forming Machine

Corrugated Iron Making Machine

Corrugated Iron Making Machine

Double Layer Roll Forming Machine

Double Layer Roll Forming Machine

Z Purlin Roll Forming Machine

Z Purlin Roll Forming Machine

C/Z Exchange Purlin Machine

C/Z Exchange Purlin Machine

Advertisement /Ceiling Panel Forming Machine

Advertisement /Ceiling Panel Forming Machine

Double Deck Rolling Machine

Double Deck Rolling Machine

Manual decoiler

Manual decoiler

Square Pipe Forming Machine

Square Pipe Forming Machine

Deck Floor Machine

Deck Floor Machine

Window Frame Box Forming Machine

Window Frame Box Forming Machine

Glazed tile roofing former machine

Glazed tile roofing former machine

Double Panel Roll Forming Machine

Double Panel Roll Forming Machine

Hydraulic Crimping Machine

Hydraulic Crimping Machine

Glazed Tile Forming Machine

Glazed Tile Forming Machine

Spare parts

Spare parts

Ridge Cap Forming Machine

Ridge Cap Forming Machine

Roof Sheet Forming Machine

Roof Sheet Forming Machine

Deck Floor Roll Forming Machine

Deck Floor Roll Forming Machine

Punching machine

Punching machine

Leveling Machine

Leveling Machine

Glaze Tile Making Machine

Glaze Tile Making Machine

Double Deck Forming Machine

Double Deck Forming Machine

Container Board Forming Machine

Container Board Forming Machine

Light Keel Roll Forming Machine

Light Keel Roll Forming Machine

Glazed Tile Roof Machine

Glazed Tile Roof Machine

Roll Shutter Door Forming Machine

Roll Shutter Door Forming Machine

Corrugated Iron Machine

Corrugated Iron Machine

Slitting Machine

Slitting Machine

Color Stone Roof Forming Line

Color Stone Roof Forming Line

Auto Change Size C Purlin Machine

Auto Change Size C Purlin Machine

Ridge Cap Tile Forming Machine

Ridge Cap Tile Forming Machine

Corrugated Metal Roofing Machine

Corrugated Metal Roofing Machine

Glazed Sheet Making Machine

Glazed Sheet Making Machine

Corrugated Roll Forming Machine

Corrugated Roll Forming Machine

Metal stud and track roll forming machine

Metal stud and track roll forming machine

Glazed Tile Roll Forming Machine

Glazed Tile Roll Forming Machine

Glazed Roof Tile Forming Machine

Glazed Roof Tile Forming Machine

Keel Roll Forming Machine

Keel Roll Forming Machine

Light Steel Profile Machine

Light Steel Profile Machine

Corrugated Iron Sheet Roll Forming Machine

Corrugated Iron Sheet Roll Forming Machine

Metal Roof Making Machine

Metal Roof Making Machine

Hydraulic Curving Machine

Hydraulic Curving Machine

Double Roof Sheet Machine

Double Roof Sheet Machine

Glazed Aluminum Roofing Machine

Glazed Aluminum Roofing Machine

Pre-cutter

Pre-cutter

Decking Forming Machine

Decking Forming Machine

C Purlin Machine

C Purlin Machine

Simple Curving Machine

Simple Curving Machine

Corrugated Galvanized Sheet Machine

Corrugated Galvanized Sheet Machine

Film Coating Machine

Film Coating Machine

Metal Profile Sheet Making Machines

Metal Profile Sheet Making Machines

Car/Container Board Forming Machine

Car/Container Board Forming Machine

Light Steel Frame Roll Forming Machine

Light Steel Frame Roll Forming Machine

Automatic Decoiler

Automatic Decoiler

EPS Sandwich Panel Producing Line

EPS Sandwich Panel Producing Line

Deck Floor Forming Machine

Deck Floor Forming Machine

Double Layer Roof Sheet Forming Machine

Double Layer Roof Sheet Forming Machine

Corrugated Aluminum Sheets Machine

Corrugated Aluminum Sheets Machine

5 Ton Hydraulic Decoiler

5 Ton Hydraulic Decoiler

Hydraulic Bending Machine

Hydraulic Bending Machine

Metal Panel Forming Machine

Metal Panel Forming Machine

Corrugated Iron Making Machine

Corrugated Iron Making Machine

Double Layer Roll Forming Machine

Double Layer Roll Forming Machine

Z Purlin Roll Forming Machine

Z Purlin Roll Forming Machine

C/Z Exchange Purlin Machine

C/Z Exchange Purlin Machine

Advertisement /Ceiling Panel Forming Machine

Advertisement /Ceiling Panel Forming Machine

Double Deck Rolling Machine

Double Deck Rolling Machine

Manual decoiler

Manual decoiler

Square Pipe Forming Machine

Square Pipe Forming Machine

Deck Floor Machine

Deck Floor Machine

Window Frame Box Forming Machine

Window Frame Box Forming Machine

Glazed tile roofing former machine

Glazed tile roofing former machine

Double Panel Roll Forming Machine

Double Panel Roll Forming Machine